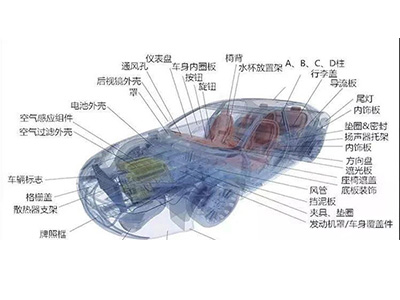

Application of 3D printing in automobile industry

The application of 3D printing in the automobile industry runs through the whole life cycle

Under the era of Industry 4.0 transformation in China, the automobile industry, as a leading pillar industry in the manufacturing industry, faces increasing pressure in manufacturing and becomes more and more important in research and development. The use of 3D printing technology to improve the production efficiency of automobiles, reduce production costs, and how to make the appearance more personalized are all issues that automobile and its parts enterprises need to consider. In recent years, many leading automobile manufacturers have applied 3D printing technology to automobile research and development.

- Modeling review

Automobile modeling creative review is an important node in automobile design, which determines the process of automobile modeling and design iteration. Because of the rapid prototyping nature of 3D printing, developers can use 3D printing technology to create conceptual models within hours or days.

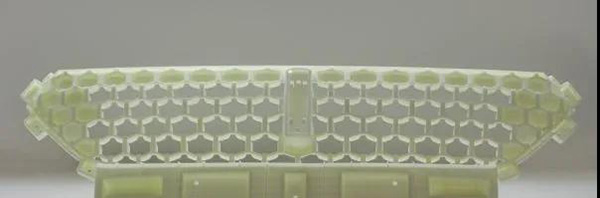

- Design, verify and test the manual samples

In automobile product development often need to the design of product reliability, installation structure and parts matching, structural strength, etc.), at the same time in order to make up for the vehicle test in the middle and later periods of the vehicle development, the design of the risk, need pre-production samples to verify the design, then can use the SLA prototype parts of the production process, function and assembly inspection.

The picture shows the protective panel on the left front door of the Harvard H2 assembled with the tweeter hood

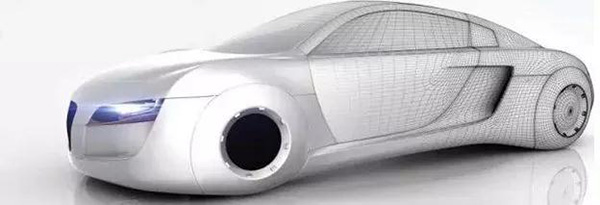

- Complex structural parts

In the development process, when the complex structural design makes it impossible to use traditional manufacturing technology for manufacturing, or the traditional manufacturing cost is very high, such complex structural parts can be printed by 3D printing, which can verify the design ideas of designers in a relatively short time and at a lower cost.

The picture shows the Harvard H2 grille cover

4. Lightweight structural parts

Automotive lightweight is playing an increasingly important role in product development. Thanks to 3D printing technology, it is possible to make hollow lightweight structural parts from plastics and even metals, instead of relying solely on foam and Mucell technology. Toyota’s lightweight 3D-printed car seats, for example, have lost 72% of their weight.

- After-sales personalized customization

In terms of personalized exterior body covers and automobile interior and exterior accessories (bumper, dashboard, car central control, spoiler, etc.), 3D printing is more and more attractive to young customers. 3D printing is most suitable for personalized customization.

3D Printing Dream Park has made a car case

This is the preliminary research and development of the front panel of automobile interior decoration. Due to the large size of the parts and the tight construction period, if the traditional CNC production is adopted, the construction period will not only be long, but the cost will be more than 10,000yuan. Due to the strength requirement of the parts, Prindream proposed to use laser-sintered nylon SLS to process the parts. The strength and accuracy of the parts produced by the SLS process can be guaranteed. The one-time printing is successful, the construction period is quickly shortened, and the development progress is accelerated, helping GM seize the market opportunity. After customers get the application, they highly approve of 3D printing technology, which will be recognized by large groups. Our hearts are greatly encouraged and we are full of confidence in 3D printing.

Conclusion

In the automotive industry, 3D printing has great advantages in terms of overall product strength, accuracy and response speed. The linkage of multiple 3D printing devices can also significantly reduce the product development cost, which is comparable to the traditional process at the present stage. With the popularization of industrialization, it is expected that the cost of equipment and raw materials will be greatly reduced. As market competition intensifies and product life cycle shortens, enterprises are increasingly aware of the importance of R&D speed and cost control, making the use and application of 3D printing in the industrial field increasingly popular.