Amazing ! Innovative 3D printing of bones

In daily life, it is hard to avoid some accidents if you are not careful, especially when exercising, many people are prone to fracture.The so-called broken bones 100 days, according to the traditional medical method, we need to put on a plaster or a bandage, and rest at home for a long time.This is a very painful thing for many people.

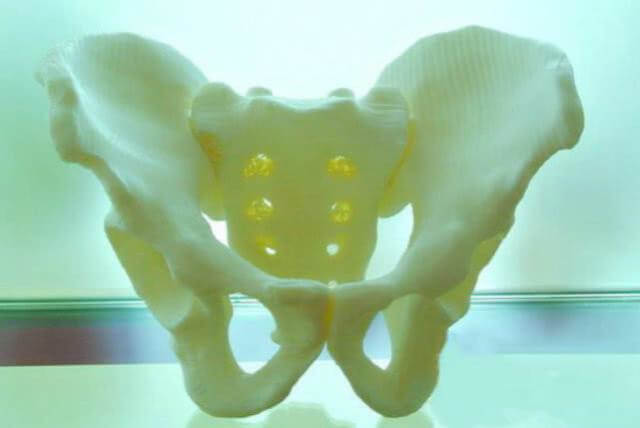

We know that a cast is put in after a fracture to help the injured bone stay stable and heal over time.In more severe cases, metal fixtures are used to help keep the bones structurally stable.Such metal devices can promote bone healing and help patients recover as quickly as possible.Due to the constraints of production technology, these metal devices are mostly round or square in shape, so their functions are difficult to satisfy doctors. However, 3D printing technology can produce artificial bones in various shapes.

Now, with the development of science and technology, experts have developed a 3D-printed bone made from bone powder and biological glue, which can be used for medical treatment, that make many netizens feel a big surprise.

Based on the original 3D printing technology, the research team of Southern Medical University in Guangzhou, China, innovatively proposed a 3D printing bone technology, which can print bone with bone powder and biological glue as raw materials.

The process is also relatively simple. First, the real bones need to be ground into powder, and then, through the action of biological glue, the bones are bonded together to make the shape we need.The new 3D printing technology is not yet widely used in hospitals and is still in the experimental stage.

The biggest advantage of the technology is that it can be printed in various shapes to suit the needs of different patients, and experts estimate it need a around decade before the technology is ready for use.

In the field of skeletal medicine, there is another therapeutic solution to repair the long bone segment defect.Dr. Szivek recently received a five-year, $2 million grant from the U.S. Department of Defense to conduct a study to determine how to use a combination of 3D printing and adult stem cells to cure fractures.

Dr Szivek, a biomedical engineer and professor of orthopaedic surgery, explained: ‘In the military, soldiers have a high frequency of accidents in combat. An explosion, an accident can lead to all kinds of bone damage.So if this research is successful, it could give them a second life.”

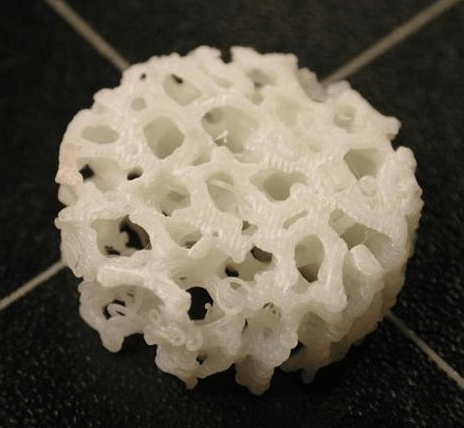

With the help of a clinical partner in UA’s Orthopedic surgery division, Dr. Szivek’s lab plans to develop 3D printed biomimetic scaffolds that can replace large, missing or fractured bone segments.The scaffolds will be filled with calcium granules and adult stem cells, two agents that are known to promote healing and bone growth.Once implanted, the scaffold serves as a template for bone growth.

Close-up shots of 3D-printed scaffolding, a plastic bone-shaped frame, will help replace missing bones.

The results in Dr. Szivek’s lab are impressive. “We were able to print the entire bone, and it took about three months to repair the broken bone.Now our goal is to speed up the healing process, “says Dr.Szivek.

The next step is to test whether exercising early in the healing process helps speed healing and recovery.To test the theory, 3D printed bone scaffolds will be embedded with tiny sensors that wirelessly transmit motion data.These sensors will analyze the load and how long it will last.If successful, Dr Szivek’s team will develop guidelines for post-operative physiotherapy for clinical trials of military personnel.

“In the body the growth gene will try to regenerate the missing bone within a few months of the injury, but this will not happen if there is no proper scaffold.That’s why we need to develop a way to grow bone as quickly as possible to help the body grow and replace it.”Dr. Szivek says he hopes the treatment will also help bone cancer patients recover after surgery.