3D Reverse scan – Restore the original look

New things can always make us happy,but when it comes old and broken,we inevitably feel sad.

Some time ago, partner C Jun’s watch chain connection is broke.

Precious watch incomplete, C junxin looks very sad for it.

Then Xiao Meng came up with a solution: use reverse scanning and 3D printing technology to create the same watchband as before.C jun feel it is reliable!

After receiving the broken watchband;the designer Wang began to work on the strap reconstruction.

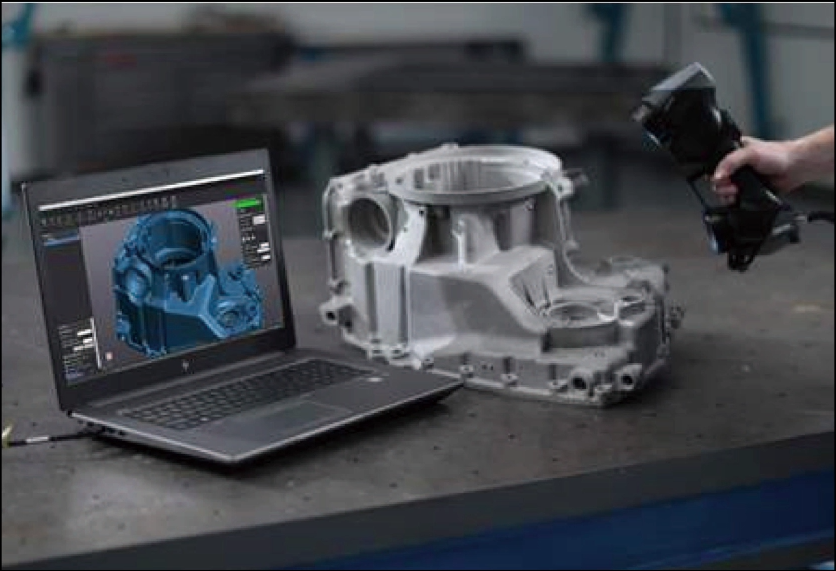

Firstly, use a 3D scanner to scan the strap to obtain the point cloud data of the strap.

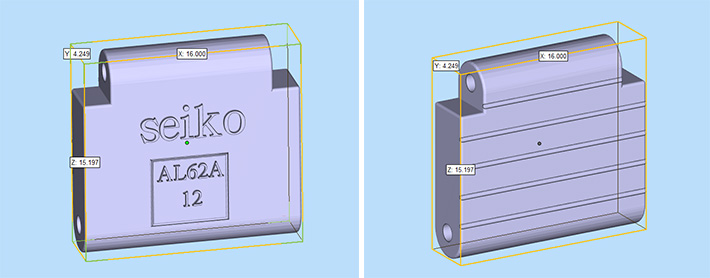

With a three-dimensional reference file, we can use it as a basis to repair the missing part and restore it to its original shape.

This is the first 3D model

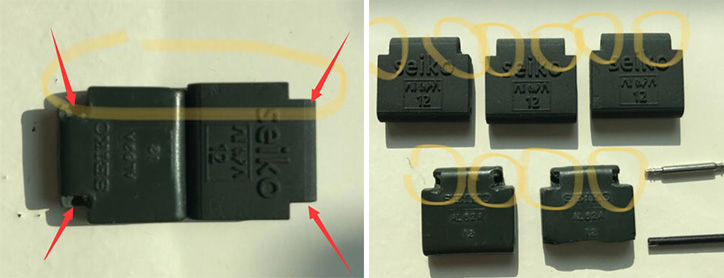

Wang thought that the part of the gap indicated by the arrow was damaged,so he filled up it, but he did not expect that it was dug by the customer himself according to his needs!

In addition, the fonts are slightly different from the original ones.

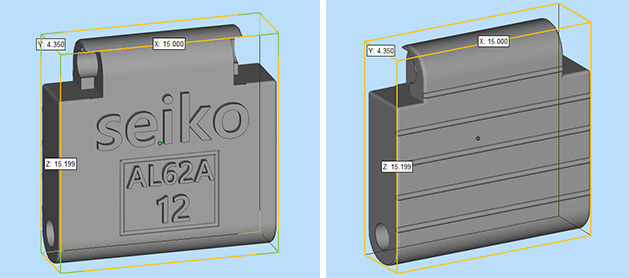

So, we produced the second model.

The rest is depend on 3D printer!

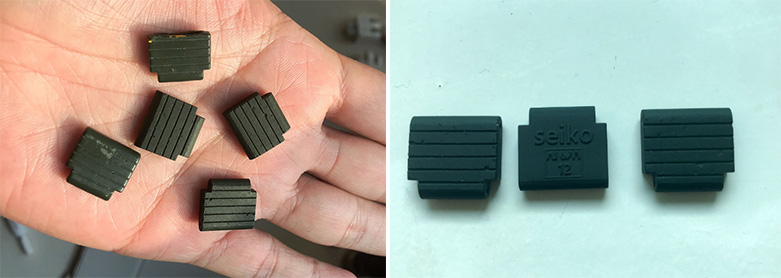

It is the white film when printed out, after processing, painting color, get the strap parts just the same as the original one.

By scanning the reverse,can make up for the defects, restore the good original things.