What do you know about design & modeling

In the past, I have shared various product examples of 3D printing. You should know that modeling is an essential step before printing.

Today, Prindream has invited Engineer Zhang, who has many years of experience in modeling and design, to share with us some requirements and matters needing attention about design and modeling. I believe this content will give you more inspiration to design products.

Appearance requirements of plastic parts

- The surface of the product shall be flat, full and smooth, excessively natural, without any defects such as collision, scratch or shrinkage cavity.

- The thickness of the product shall be uniform and consistent, without warping deformation, flying edge, burr, material shortage, water wire, flow mark, fusion mark and other defects affecting the performance of injection molding or 3D printing. Burr and gate should be all cleaned and trimmed.

- The color and luster of the product should be uniform and consistent, with no obvious color difference on the surface. The original color of the parts should be consistent with the color of the raw materials, and uniform; The parts to be matched with colors shall meet the requirements of the swatch.

- The external dimensions of upper and lower shells are inconsistent, that is, the surface scraping (the surface scraping is larger than the bottom shell) or the bottom scraping (the bottom shell is larger than the top shell).Acceptable facial scraping < 0.15mm, acceptable bottom scraping < 0.1mm. Therefore, when zero segment difference cannot be guaranteed, try to make the product: surface > Pan.

Generally speaking, as for the surface shell, because there are more key holes, forming shrinkage is larger, so shrinkage rate choice is larger, generally choose 0.5%, as for bottom shell, forming shrinkage is smaller, so shrinkage rate choice is smaller, generally choose 0.4%.

General principles of structural design

- Strive to make the product structure simple and easy to shape;

- Uniform wall thickness;

- Ensure strength and stiffness;

- Determine the shape, size, appearance and materials according to the required functions. When the product has a high appearance requirement, the internal structure should be designed after the appearance modeling.

- Try to design the product into a rotating or symmetrical shape. This shape structure has good manufacturability and can withstand greater forces, and the mold design is easy to ensure temperature balance and the product is not prone to warping and other deformation.

- Considering the fluidity, shrinkage and other characteristics of plastics, all corners of the parts shall be designed into rounded corners or arc transitions as far as possible under the premise of meeting the requirements of use.

Design essentials of plastic parts

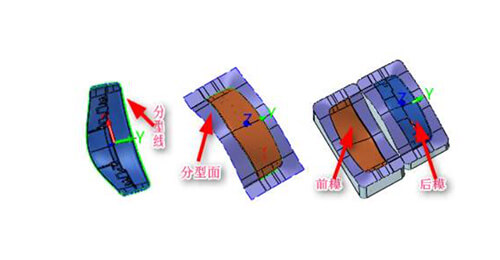

Die opening direction and parting line

At the beginning of the design of each plastic product, the mold opening direction and parting line should be determined first to ensure that the core-pulling mechanism is reduced as much as possible and the influence of parting line on appearance is eliminated.

After the mold opening direction is determined, the stiffeners, buckles, bumps and other structures of the product shall be designed to be consistent with the mold opening direction as far as possible, so as to avoid core-pulling to reduce the stitching line and prolong the life of the mold.

Appearance and wall thickness

The wall thickness should not be less than 0.6~0.9mm in general, and 2~4mm is usually selected.

- The wall thickness shall be uniform and the thickness difference shall be controlled within 25% of the basic wall thickness as far as possible. The minimum wall thickness of the whole part shall not be less than 0.4mm.

- The shell thickness in the direction of thickness should be 1.2~1.4mm, and the side thickness should be 1.5~1.7mm; The supporting surface thickness of the outer lens is 0.8mm, and the minimum thickness of the inner lens is 0.6mm.

Plastic molding process and use requirements of plastic parts of the wall thickness are important restrictions.

The wall thickness of plastic parts is too large, not only will increase the cost because of too much material, but also bring some difficulties to the process, such as extending the molding time (hardening time or cooling time).It is unfavorable to improve the production efficiency and easy to produce bubble, shrinkage hole and sag.

Plastic piece wall is thick too small, melt plastic is in mold cavity flow resistance is big, especially shape is complex or large plastic piece, molding is difficult, because wall is thick too thin at the same time, plastic piece strength is poor also.

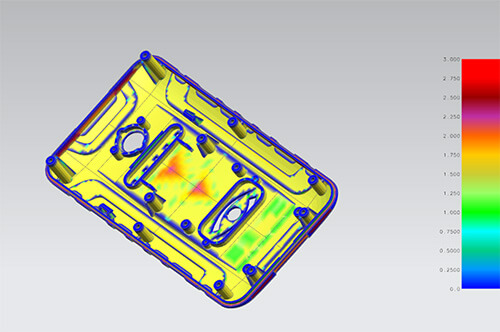

Plastic parts in the case of ensuring the thickness of the wall, but also to make the wall thickness uniform, otherwise in the molding cooling process will cause uneven shrinkage, not only bubbles, depression and warping phenomenon, at the same time in the plastic parts there is a greater internal stress.

When designing plastic parts, thick wall and thin wall junction to avoid acute Angle, transition to ease, thickness should be gradually reduced along the direction of plastic flow.

The main factor that determines wall thickness

- Whether the structural strength and stiffness are sufficient;

- Can it withstand the push out force of the push out mechanism without deformation when stripping;

- Whether the impact force can be evenly dispersed;

- Whether the embedment can prevent rupture;

- Whether the fusion line of the hollow part will affect the strength;

- Can withstand the fastening force during assembly;

- Whether the edges and corners and thinner wall thickness will impede the material flow and cause insufficient filling. The wall thickness is too small, the flow resistance of molten plastic in the mold cavity is large, difficult to fill, the strength and stiffness difference; The wall thickness is too big, the inside is easy to get angry bubble, the outside is easy to produce shrinkage sag, and the cooling time is long.

In general, when the wall thickness is less than 1mm, it is called thin-walled. Thin-walled products are molded at high pressure and speed, and their heat is quickly carried away by mold inserts, sometimes without cooling water.