Used to love your song, but the world won’t be as gentle as the song – Gundam

With the increasing maturity of 3D printing technology, more and more garage kit enthusiasts make hand models through 3D printing, which has a certain impact on the garage kit industry. The advantage of 3D printing garage kit is that it can restore the model with 100% accuracy without any fault. Compared with the traditional garage kit, it has some lamination. For enthusiasts with high requirements of garage kit detail texture, the traditional garage kit process is the best choice.

Today we bring you the hero – the robot fighter Gundam

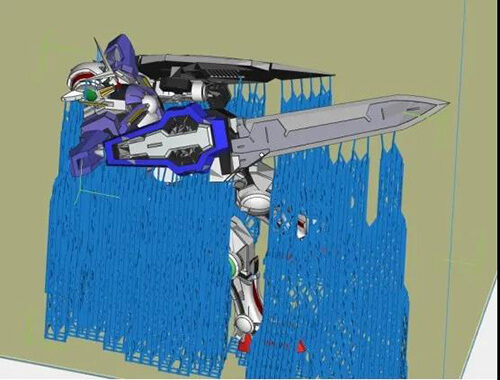

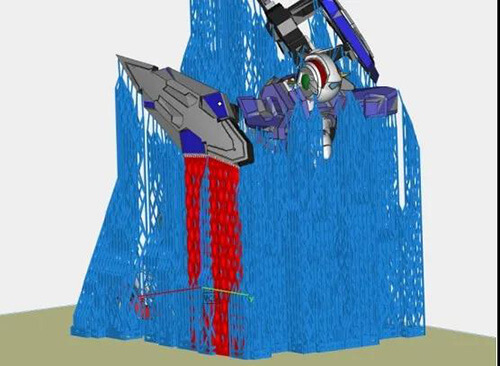

The difficulty of this garage kit is that there are many details and many small parts. The parts in some places are sharp and easy to be broken. Therefore, extra attention should be paid to the support and post-treatment.

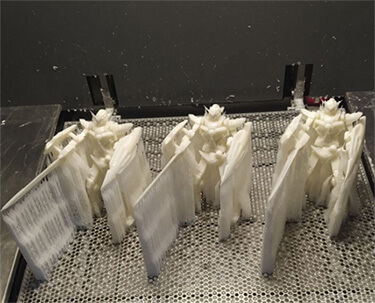

Adding support

For the sharp parts of the details, it is necessary to avoid adding support. It can be placed upward in an oblique way to avoid adding support. For the suspended parts that need to bear the weight, it is necessary to manually add some support to prevent the parts from being fixed unsecurely during the printing process and the parts from being damaged due to displacement.

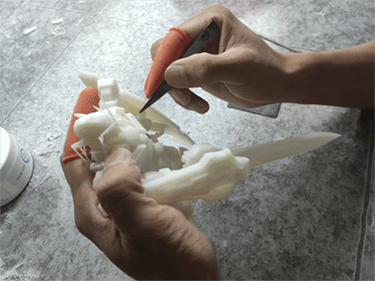

The post-printing processing

The aftertreatment masters remove the supports and grind the parts.

During post-treatment and polishing, it is necessary to clean the small supports under the armor, and pay attention to the detail support points during polishing, so as not to leave pits on the surface.

After spraying sand the gundam white, you can make it in your own color.