The best way to produce 3D printing cases quickly and in small quantities

3D printing has unique advantages in product concept design, prototyping, product review and functional verification. 3D printing can produce product prototypes quickly and with high precision. This paper introduces the process of small batch rapid manufacturing from 3D printing product prototype.

This time, a customer needs 100 sets of hand plate models, which are used for assembling the controller shell, and the delivery cycle is only one week. The customer wanted to use mould opening process before, but the long cycle and high cost could not meet the delivery time. With 3D printing, it takes only 10 hours to complete, with delivery the next day. For the production of small batch products, 3D printing is a very good choice, not only short cycle and low cost, but also the delivery speed is much faster than the mold opening.

Before processing

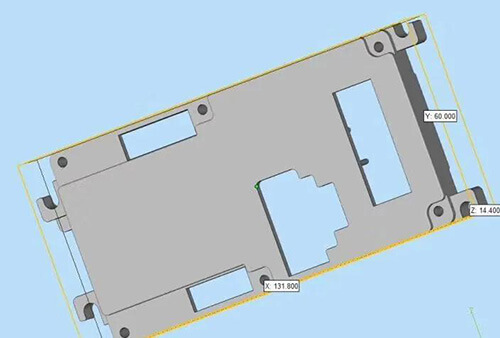

Modelers have optimized the pre-processing according to the needs of users. According to the drawings sent by customers, we choose the photocurable SLA6003D printer to achieve rapid molding. Its high speed, high precision, smooth surface, easy to do post-processing, high production efficiency is the biggest advantage.

post-processing

After printing, the white photosensitive resin is sandblasted to ensure the smoothness and structural strength of the model surface. 3D printing solves the problem of too long production cycle of traditional technology well and reduces the waiting time of customers.

The above is the process of making prototypes quickly and in small batches with the help of 3D printing technology. Prototyping with this technology is an effective means of making prototypes in small batches with high precision, low cost and high efficiency. Imoyuan 3D printing service can help customers successfully carry out small batch mass production.