Aero engine model, 3D printing to help the aerospace industry!

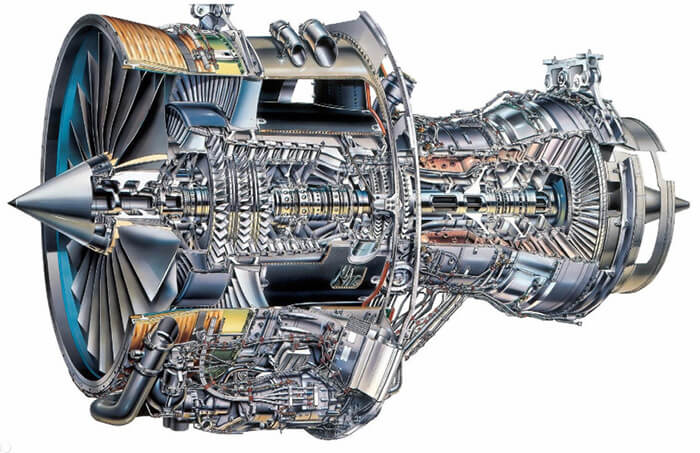

Aero engine is a highly complex and precise thermal machinery. As the heart of aircraft, aero engine is not only the power of aircraft flight, but also an important driving force to promote the development of aviation industry. Every important revolution in the history of human aviation is closely related to the technological progress of aero engine.

Today I’m going to share a model of an aero engine.The restoration, splitting, printing and post-processing of the model are all undertaken by our company. The designer combined with 3D printing technology and made some changes to the structure of the model after obtaining the consent of the customer,they are very satisfied with the final effect.

This engine model is a exhibition model. At the first time,the customer looked for a 3D printing supplier in Guangzhou, but it was easy to be damaged in the transportation because of the long distance. So he deliberately looked for a partner nearby his company and finally found us.Our company ocated in Shanghai, so we can make full use of geographical advantages to better provide services for customers in Jiangsu, Zhejiang and Shanghai!For more distant areas, we use SF express for delivery to minimize damage during transit.

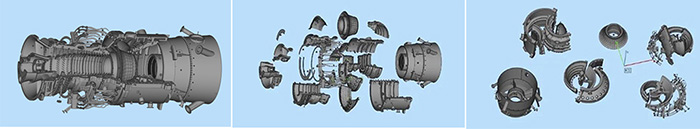

This is the original drawing, and it took half a day just to open the parts (no exaggeration)!The files are complicated!There are a lot of bad places!The main wall thickness is not enough, the main body is only a little more than a millimeter, and there are many holes and interlayers, the primary problem is still photoshop, and this glorious task fell on our rising star Wang Gong!

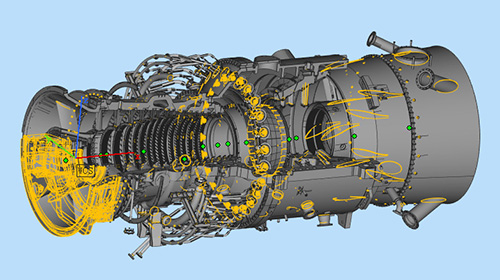

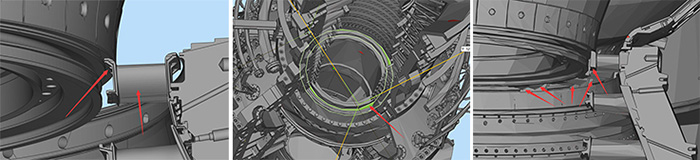

As the picture shows the support part of the original image is only a pillar, and little, thin hook contact, the designer worry about it can’t afford to support later, after communication with the client, the designer will be filled in the middle of hook, increase the intensity of support, and in the same horizontal plane to increased within a circle pillar, scattered single pillar bearing weight, make assembled more firmly.To this end, someone once asked: can this bear it?Wang Gong is not in a hurry to sing the song: a chopstick yo, gently broken, ten chopsticks yo, firmly hold into a ball!

The green part is not shown in the original drawing. The shape of parts inside is large at both ends and small in the middle, which may lead to the failure of assembly.After Wang reminded the customer, a ring of shell was added on the underside to connect two independent parts and combine them into a whole, thus solving the problem of difficult assembly in the later stage.

The repaired model is very large, so the designer must reasonably dismantle the parts according to the size of the printer platform and the later assembly, and make a good structure between the assembly parts to ensure the robustness of the overall model.

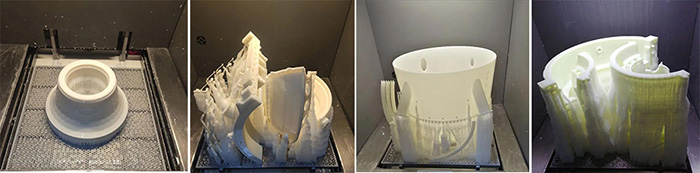

The whole set of parts should be printed by machine separately to avoid being mixed with other customers’ parts.Among so many parts, only one rotating shaft has some micro-printing deformation, while other parts are perfectly formed. We also arranged the replacement of that deformed rotating shaft at the first time, which did not delay the customer’s construction period.

Every part in the hands of the post-processing master will be treated seriously, then coming out will look brand-new!

Due to the complexity of the model, in order to avoid damage in transit, the customer personally came to our factory to pick up the goods after completion and only get them back before installation. Therefore, we were very sorry that we did not see the finished product picture after installation. However, the surprise in the customer’s eyes when picking up the goods was a great encouragement to us!