3D printed ship model

In ancient times, people lived along the river, so the water transportation was essential if they wanted more food sources and more communication

From bamboo raft to sailing boat, from wood pulp to rowing, from a canoe to a deep-sea giant ship, all witness the history of the ancient working people constantly exploring and conquering rivers and seas.

Even the ancient poetry is not lacking in the figure of the ship:

At the foot of Pengcheng mountain,

Along with the Ancient Bian river,

The ship is carrying Liangzhou.

In film and television, the theme of the ship is endless,such as the <perfect storm>, <Titanic>

Ships play an indispensable role in human life.

Today I’m going to share a case about ships.

1.Preparation and quotation

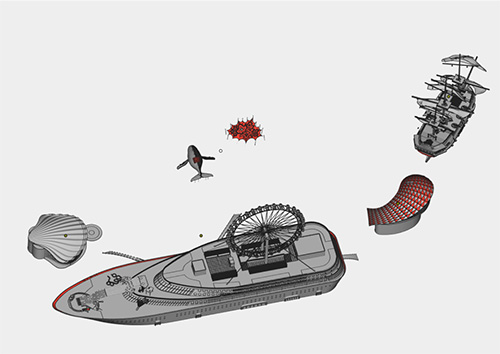

The client initially provided a 3Dmax file, which was transferred out to 2.5g. There were a total of six models, including boat, shell, shark, etc., all of these needed to be printed. The file was very large and it was very hard to open.

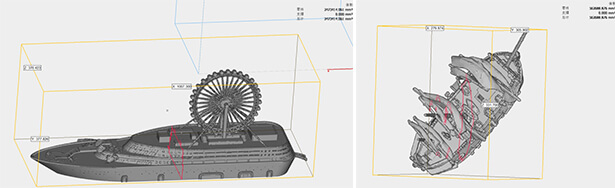

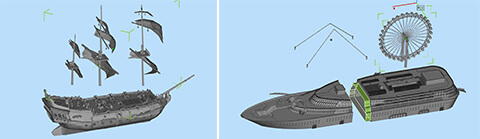

There are many problems in the drawings: the hull has no thickness;The splint is not connected to the hull;The size of the railings, Windows and other decorative patterns on the ship is only 0.1mm, which cannot meet the printing requirements, so it needs to be enlarged and thickened.In addition, there are some holes, bad edge, cross overlap surface, without repair can not be printed on the machine.However, the customer wants to know the general printing price first, so we can only make a simple package to get the general weight first, and then give a reasonable quotation.

- Retouching and splitting

In the process of drawing repair, in order to better understand the needs of customers, we built a group of businesses, communicated with customers directly in design and solved problems at any time, which was clear, convenient and quick to solve problems.Designers do mental calculations;The customer actively cooperated and finally completed a complete set of model repair project after 5 days.

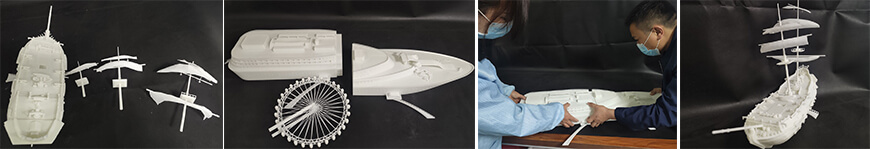

As the length of the ship is over one meter, we need to cut it in the middle and print it in two sections.In order to ensure the printing effect, the designer took apart and printed the decorative items and thin rods on the ship separately, and made the bolt structure to facilitate the later assembly.

The adhesive joint of ship hull extends inward, increasing the adhesive contact area and making the assembly more firm.

- add support, print, post-processing

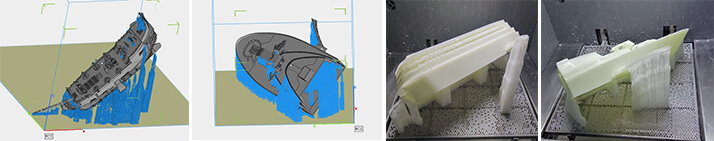

When adding support frame, in order to ensure the surface quality, repeatedly adjust the placement angle to reach the most appropriate position, minimize lamination and reduce the amount of support.For something big like this, a 3d machine need take 40 hours of continuous printing to complete.When it got off the machine, I washed the parts with alcohol, supported them and polished them to get the finished products.

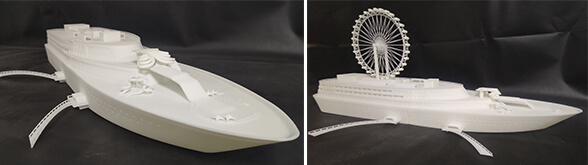

The final product is also very beautiful.

However, the good time is rare, and the matter is not over satisfactorily: the customer told us that the size of the ship was wrong after receiving the goods!After receiving this amazing news, our salesman went to the customer’s compamy to measure the size at the first time and looked for the reason. Finally, we found that the customer mistakenly took the size of the bottom of the ship as the overall size, resulting in the print size being smaller than the actual size.

Considering the limited budget of the customer, we are also in line with the original intention of helping the customer to solve the problem as far as possible. After the salesman reported and applied to the leader, we finally agreed to charge only one cost price and then help the customer to revise the size and arrange printing.At the same time, the client proposed that the two pillars at the ferris wheel of the big ship were not firmly assembled, so the designer accepted and adjusted the two pillars into five pillars after reaching an agreement with the client, so that the assembly would be more stable.

After the size is adjusted, we will arrange reprinting, and let the bulk goods be delivered directly to your door. The customer is also very grateful that we can be urgent for the customer, and said we are a solid partner!

Related projects